Collado Engineering is pleased to announce the promotion of Miguel Quintanilla, P.E., to Principal and Alberd Misku, CPD, to Associate.

Miguel Quintanilla, P.E., LEED AP Principal

“Miguel has held the reigns, as a department head, of our Plumbing and Fire Protection department. As our newest Principal, we welcome him to our leadership team and are confident that he will continue to contribute to the growth of the firm,” said Andrew Hlushko, Collado Engineering’s President.

Miguel has worked in the industry for 20 years after graduating from Stevens Institute of Technology with a Bachelor of Engineering in Mechanical Engineering. He is licensed in NY and four other states, is a certified LEED AP, and is an active member of the American Society of Plumbing Engineers and the National Fire Protection Association.

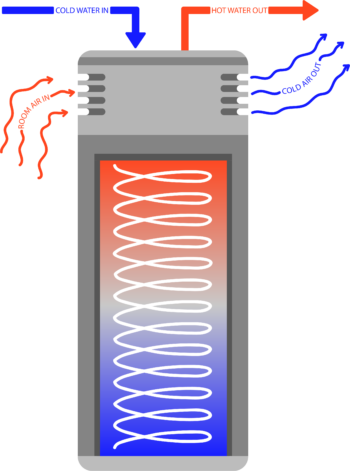

Miguel is currently leading Collado’s effort on the energy performance-based MEP system upgrades at the NYCHA Adams Housing Complex. The work is focused on the central heating plant serving the seven residential buildings in the complex including refurbishing the steam boilers, decoupling the domestic hot water from the boiler plant, and electrifying the system using heat pump water heaters.

“I am honored to become a principal at Collado Engineering, and I appreciate the opportunity to be part of its leadership team,” said Miguel about his recent promotion. “Collado’s mission, to provide value to our clients through our expert quality work, resonates with my core beliefs as a consultant.”

Alberd Misku, CPD Associate

Alberd Misku, CPD Associate

“Alberd has been a part of our firm for nine years and has become a key member of the Collado team working on projects that range across the architectural engineering spectrum. We are thrilled to promote him to this important position,” said Andrew Hlushko.

He is a graduate of Rochester Institute of Technology with a Bachelor of Science in Mechanical Engineering Technology and is a Certified Plumbing Designer by the American Society of Plumbing Engineers, of which he is an active member. He is also a member of the National Society of Professional Engineers and the National Fire Protection Association.

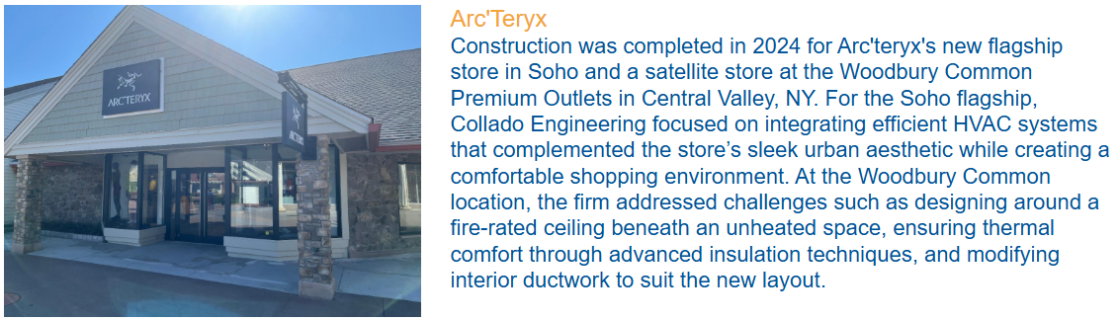

Alberd is a member of the Collado team that is currently working on the new Graduate Hotel in Princeton, NJ. Once complete, the hotel will have a total of 148 guest rooms, street-level lobby, food and beverage space, and on-site laundry. Collado is designing the MEP systems for the new building, as well as the renovation of the existing building.

“Collado was my entrance into the consulting engineering world and ascending to the Associate level highlights the confidence the principals have in me, as well as my commitment to the firm,” explains Alberd. “I am excited for the future and look forward to contributing to the firm’s innovation and growth.”

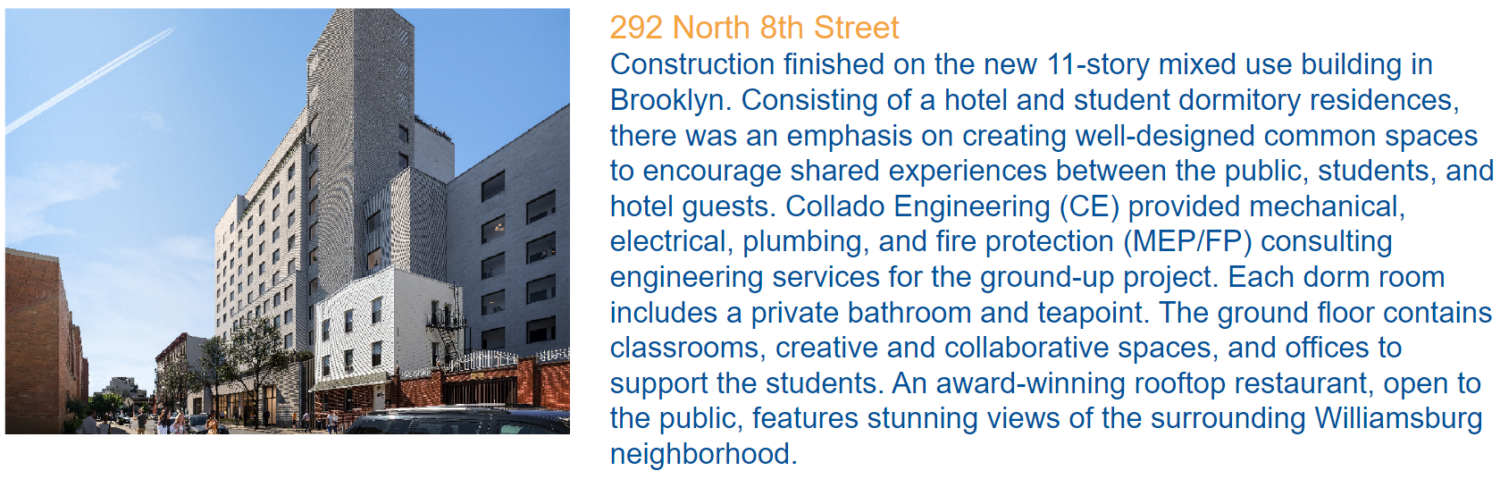

Case Study:

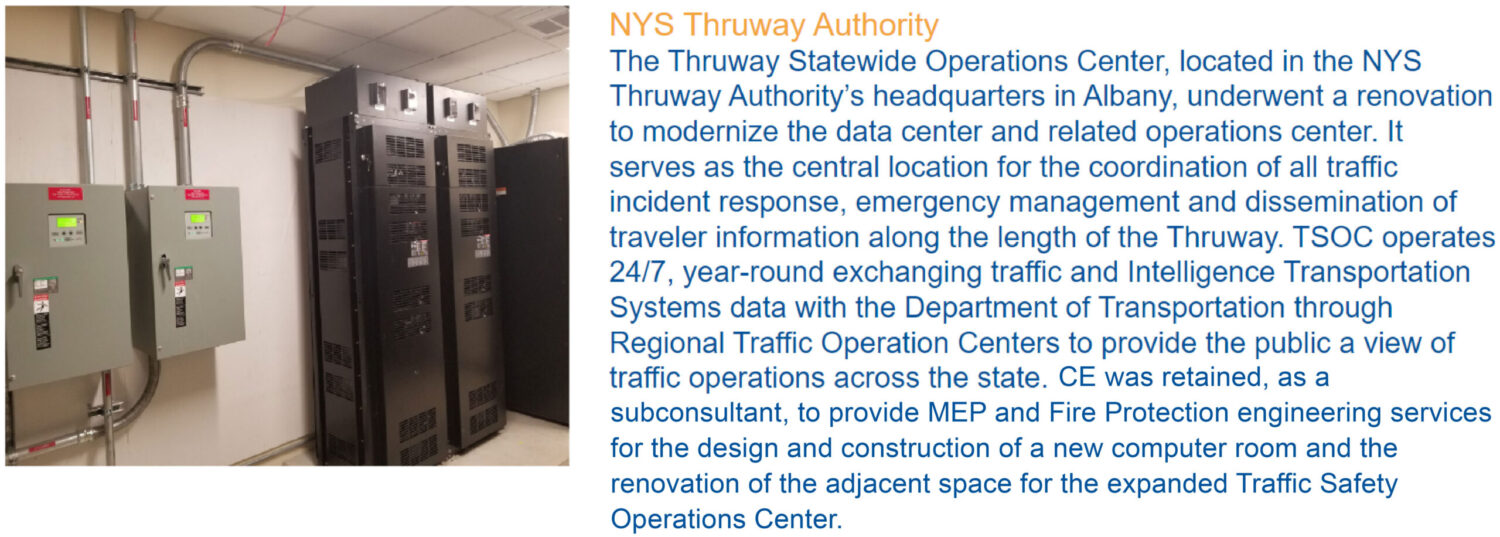

Case Study:

Alberd Misku, CPD

Alberd Misku, CPD