WHAT YOU SHOULD KNOW ABOUT FIRESTOPPING

March 22, 2021 Newsroom

While firestopping and firestopping inspections have been required for a long time, they are not always given the attention they deserve. The A/E industry has developed a false sense of comfort in simply seeing the red goop (intumescent fire sealant). It is not that the industry does not think fire stopping is important, the issue is that there is a lack of understanding of the basic requirements. Currently, there is a renewed effort by municipalities to ensure that firestopping and firestopping inspections are performed properly.

Let us look at what firestopping is, and why we should all be paying more attention to it.

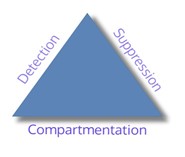

Compartmentation is a passive fire protection system designed to impede the spread of fire and smoke. It is a key component of the life safety triangle and has been a Code requirement for many years. Firestopping is an enhancement of that system, it is used to seal around openings and between joints in a fire-resistance-rated wall or floor assembly; ensuring the fire rating of a compartment is achieved or maintained. Compartmentation, and the required separation of adjacent spaces, is the purview of the architect, as is the construction of the barriers to achieve the necessary separation and the sealing of joints between these barriers.

However, penetrations through the fire rated barrier are usually required to accommodate the passing of building system components, which is typically the responsibility of the MEP engineer, and the focus of this article.

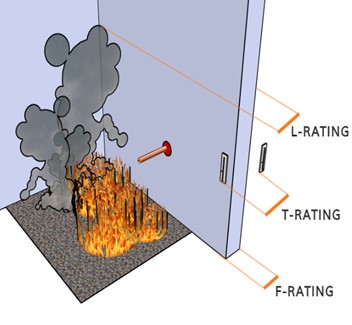

It should be noted that the “time” fire rating criteria commonly used, is only one of several criteria that must be defined to properly treat the penetrations.

F-Rating: The amount of time, in hours, before a fire spreads from the fire side to the non-fire side of a fire-rated assembly (e.g., by burning through each successive layer of materials).

T-Rating: The amount of time, in hours, before the temperature of the non-fire side of the fire-rated assembly or penetrating item reaches 325°F. Even if the fire barrier prevents the passage of flames during a fire, it is possible for the surface temperature of the non-fire side to become high enough that flammable items (e.g., lampshades, paper, fabrics, etc.) may spontaneously combust.

T-Rating: The amount of time, in hours, before the temperature of the non-fire side of the fire-rated assembly or penetrating item reaches 325°F. Even if the fire barrier prevents the passage of flames during a fire, it is possible for the surface temperature of the non-fire side to become high enough that flammable items (e.g., lampshades, paper, fabrics, etc.) may spontaneously combust.

L-Rating: The amount of air, in CFM/ft2, that leaks through a joint or penetration firestopping system at ambient temperature and at 400°F.

W-Rating: The watertightness of a firestopping system measured against 3 feet of standing water for 72 hours. The intent of the W-Rating is to gauge the extent to which a fire barrier installed in floors will deteriorate when exposed to moisture.

Other: Mold and mildew resistance and seismic performance may also need to be considered based on the specific use case.

The selection of firestopping caulk is unlike other items design professionals specify. By now most design professionals have caught-on that firestopping should be a system, and their documents call for the use of firestopping systems, and some, even call for a UL-listed system to be used. What is often not understood, is that the system is made up of the penetrating item (copper pipe, EMT conduit, etc.), penetration size, the barrier material being penetrated, the annular space between the penetrant and the barrier, and even how the penetrant passes through the barrier. Add to that the required performance criteria and you have the system. Now, find a caulk that has been tested under those conditions, and all that is left to do is ensuring that it is installed in accordance with the way it was tested and listed. Not so easy, right?

Firestopping systems must be tested and approved for use by a Nationally Recognized Testing Laboratory (NRTL). NRTLs, such as UL, list systems for the specific conditions under which they were tested. If the same caulk material, penetrant, and barrier material were not tested in a specific arrangement, it would not carry a listing for that arrangement. While there are thousands of listed firestopping systems from many manufacturers that cover most common configurations, installation conditions and rating requirements, there may be instances when the installation does not match the listing exactly, and an Engineering Judgement (EJ) may be required from the fire caulk manufacturer. An EJ is a written document, usually in the form of a letter or report, stating that a given firestopping installation is likely to be effective in preventing the spread of fire and smoke even if it was not actually tested in that specific arrangement. EJs should only be used as a last resort; if a project requires more than a couple of EJs, it may be a sign that not enough effort was spent in selecting the firestopping systems.

Since the selection of firestopping systems requires knowledge of how the penetrants are installed through the rated partitions, it is impossible to specify firestopping systems on the design documents. Design professionals should provide a performance specification and enough details for the contractor to be able to select an appropriate system during the construction. For example, the L, T, F, and W-Ratings should be clearly identified, as well as details of the special inspection requirements.

So, what about those inspections?

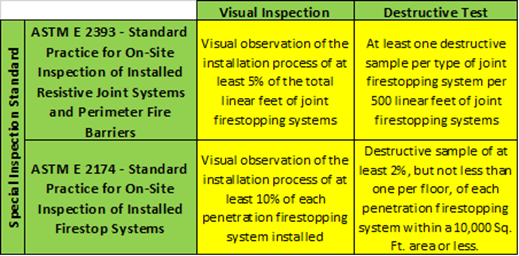

The International Building Code has included new firestopping inspection standards, since the 2012 codes were adopted. These standards were put in place to help increase the efficiency of firestopping systems and inspections. The ASTM firestopping inspection standards have also been adopted into the 2014 NYC codes. The two relevant ASTM Standards are E-2174 (Penetrations) and E-2393 (Joints); among other things, they require the firestop inspector to be completely independent of and divested from the installer, contractor, manufacturer, or supplier.

Special inspections require either visual inspection or destructive testing of each firestopping system installed on a project. Ten days prior to the installation of the firestopping materials, the contractor is responsible for providing the special inspector the installation schedule, NRTL listings for each unique firestopping system being used on the project, and any other material the inspector may require. Visual inspection requires that the inspector witness the installation of a percentage of each firestopping systems being used to ensure they are installed per the listing criteria. Destructive testing requires the contractor to cut into a small percentage of installed firestopping systems to determine if they were installed in accordance with the listing criteria. Destructive testing is the only option when the installation has not been coordinated with the special inspector and might also be used if the inspector cannot spend all that time in the field. It is important to note that the contractor will be responsible for completely removing and reinstalling the firestopping systems that have been destructively tested once the inspection is completed. To avoid costly change orders during construction, the design professionals should make the contractor aware, via the design documents, that destructive testing may occur. Table 1 details these requirements.

Effective fire stopping is essential to ensure the passive fire protection systems of the building perform as expected. All involved must have a deep understanding of the requirements and each other’s role in the process.

BY: Alec Raia, Danielle Koch, Daniel Lennon